Uni-Hydro PRO 80 Ton Ironworker

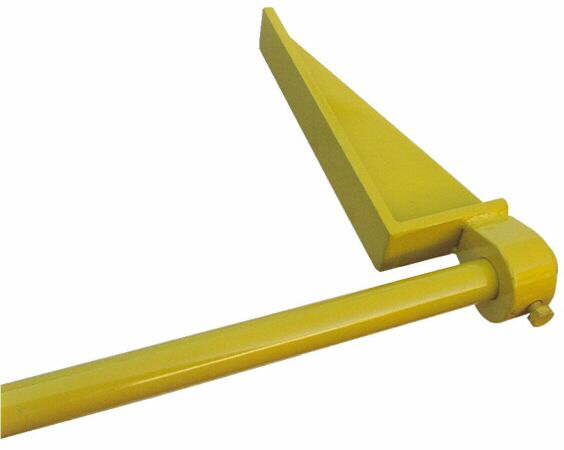

* Shown with optional Slug Type Angle Shear

DESCRIPTION:

Uni-Hydro’s PRO 80-24 is a true 4 station ironworker. We do not weld a notcher on our machines and charge you thousands of dollars. The industry considers a welded notcher a 4th station, NOT US! The PRO Series of Uni-Hydro are machines designed with;

A Flat Bar Shear

A Power Cavity

A Punch Station and

A Notching Station

FEATURES:

80 ton open throat punch

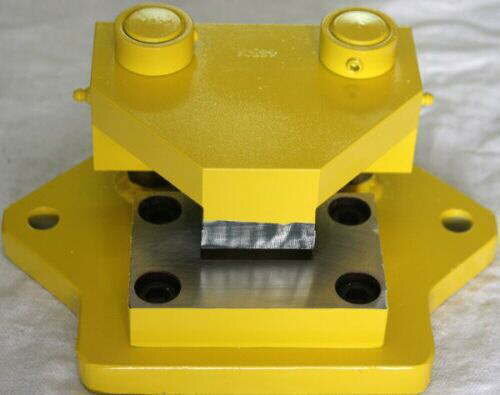

24" Bar Shear with 4 sided blade

Manual punch aligner

2-1/4″ Stripper

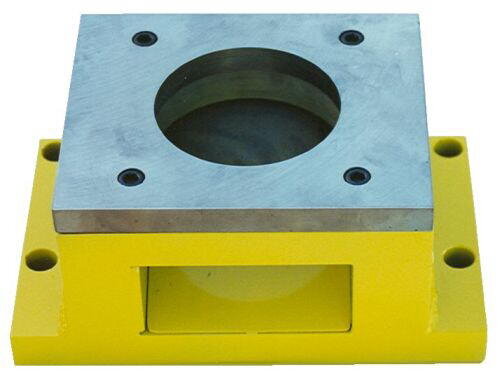

L150 and 500 Series punch & die adaptor kit that accepts up to 2-1/4″ dia punching

Magnetic starter for safety & reliability

Fixed or adjustable flat bar shear hold down

Variable stroke control

Full 4th Notcher Station - Choice of Square, V Copper or Pipe Notcher

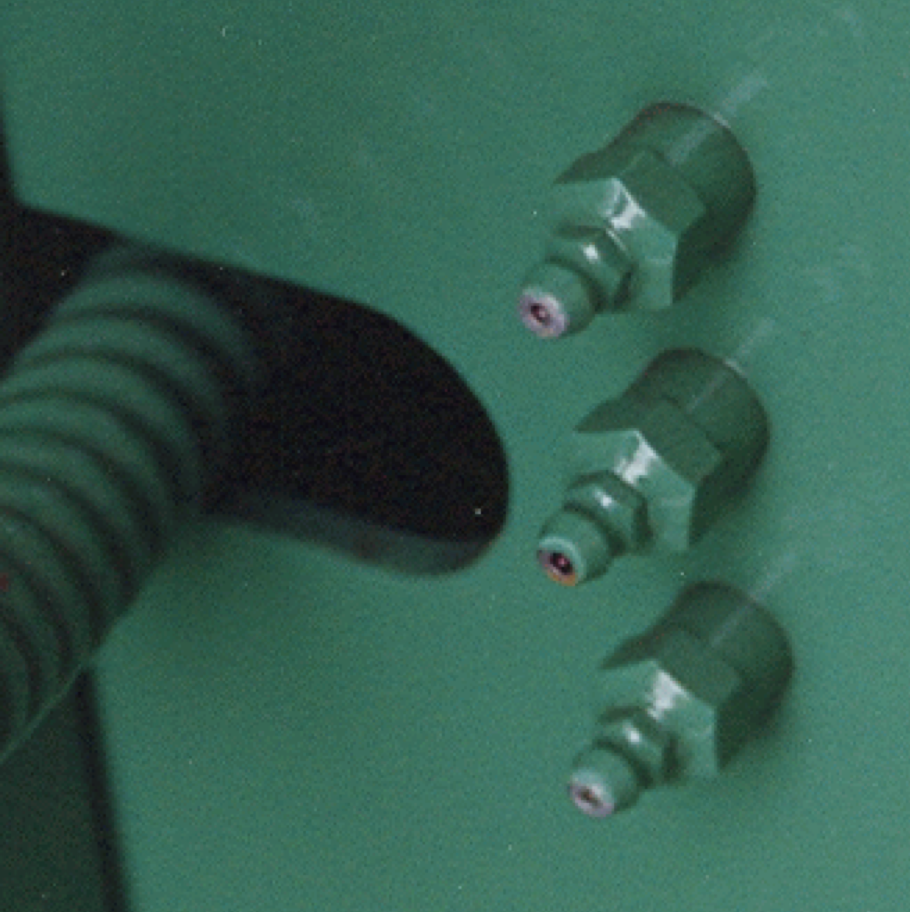

Grease bank for lubricating machine without removing covers

Electric foot control

Eyelet & forklift accomodations

PRO Series 80 ton ironworker Specifications

Model PRO 80-24

Tonnage 80

Throat Depth 9"

Punch

1-3/8" hole in 3/4" mild steel

2-1/4" hole in 7/16" mild steel

Bar Shear

1/4" x 24" , 1/2” x 20”

3/4” x 10”, 1” x 6”

Angle Shear 90°

Slug Type - 6" x 6" x 1/2"

Sever Cut - 4" x 4" x 3/8"

Miter Angle 45°

Slug Type - 4" x 4" x 1/2"

Sever Cut - 4" x 4" x 3/8"

Rod Shear

Round (Max) - 1-1/4"

Square (Max) - 1-1/4”

V Coper Notcher 90°

Notcher Station 3" x 3" x 1/4”

Punch/Power Cavity 4" x 4" x 1/2”

Square Notcher

Notcher Station 2" x 3" x 3/8”

Punch/Power Cavity 3" x 3" x 3/8”

Pipe Notcher (Sch 40 or 80)

1/2", 3/4", 1", 1-1/4", 1-1/2", 1-3/4”, 2"

Brake

6", 9”, 14”, 18”, 24” capacity

Channel Shear

2" & 3" combined or 4", 5”, 6” standard

Strokes Per Min

Light Material - 50

Max Capacity - 9

Hydraulics 2,000 psi

Oil Capacity 16 gallons

Motor

Standard - 7.5 HP / 220v / 3ph

Optional - 7.5 HP / 1ph

Dimensions

(L x W x H) 46" x 37" x 70"

Bar Shear Work Height - 29"

Punch Table Top Height - 39-1/4"

Cavity Table Top Height - 41"

Notcher Station Work Height - 31”

Weight - 3,100 lbs

Station Tooling Options:

Punch Station - For 3x3x1/4 Angle Iron, Notch V from Middle of Angle or Notch a Square from end

Punch Station - For 1/4” thick material, need Model & Serial # for Free Pusher Size 1-1/2 x 2 x 1/4

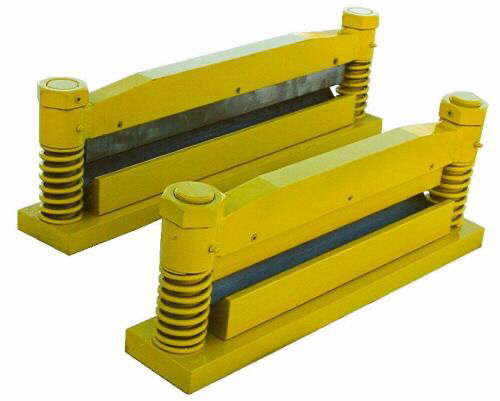

Each blade is for cutting a different size and type of stock. Angle, Channel, Rod, Z&T

Depending on the thickness of the steel and the tonnage required, there is a sever plate available in most shapes and styles.

Optional Accessories:

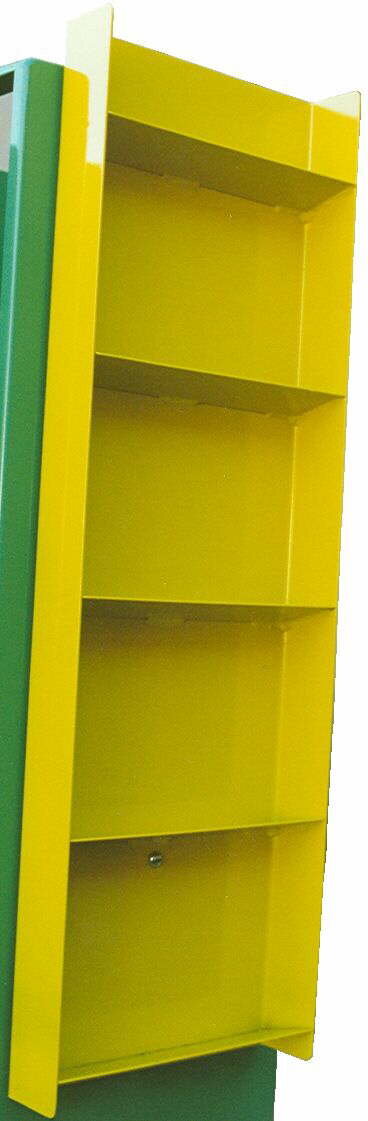

Punch tables are impregnated with oil like our punches to keep the area free from rust.

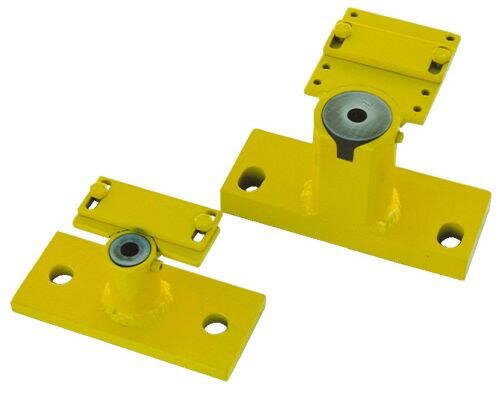

In the front is a S-Series offset die stand and behind it is a L100 Series offset die stand.

Uni-Hydro Inc. reserves the right to change specifications and options for machine models at any time without notice. Available options and tooling may vary depending on specific model capacity, all of which are outlined in formal quotes generated by our sales team. Photos of machinery may show optional tooling for marketing purposes.

Quick Links To Additional Models:

30 Ton | 40 Ton Turret | 45 Ton | 56 Ton | 56 Ton 5624 | 56 Ton Super Turret | 80 Ton

PRO 56-14 | PRO 80-24 | PRO 105-24 | PRO 125-24 | PRO 135-24 | PRO 150-24